Unleash the Power of Your 3D Printer A Beginner s Guide to Modeling and Printing

The Complete Beginner's Guide to Buying Your First 3D Printer in 2023

The 2 main types of consumer 3D printers are FDM (Fused Deposition Modeling) printers and resin 3D printers, each with its own strengths and considerations. Understanding the differences between these methods can help you make an informed decision based on your specific needs.

FDM printing, also known as filament-based printing, involves melting and extruding a thermoplastic filament to build objects layer by layer. This technology is widely accessible and offers a range of affordable 3D printers. FDM printers are known for their versatility and ability to handle a wide variety of filaments, including PLA, ABS, PETG, and more. They are suitable for various applications, such as prototyping, functional parts, and larger-scale prints. FDM printing also allows for easy post-processing and modification of printed objects.

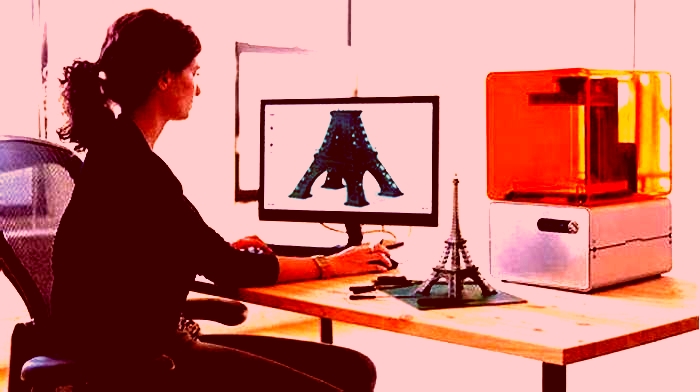

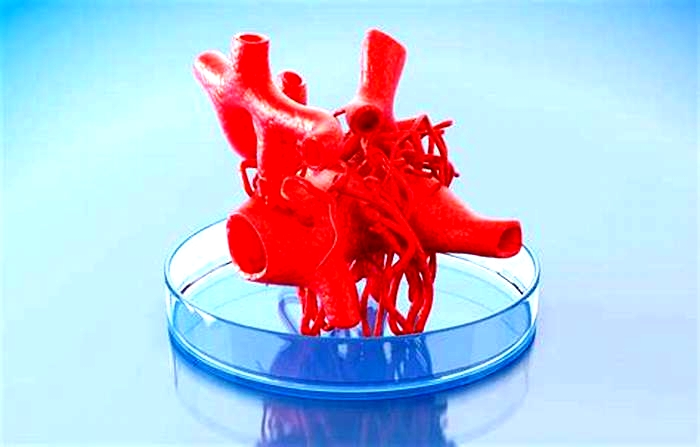

On the other hand, resin printing also referred to as stereolithography (SLA) or digital light processing (DLP), uses a liquid photopolymer resin that is cured by a light source, typically an ultraviolet (UV) laser or an LCD panel. Resin printers produce highly detailed, smooth, and precise prints with intricate geometries. They excel in producing small-scale models, jewelry, dental and medical applications, and other objects that require fine details and high-resolution output. Resin printing offers a wide range of specialized resins, including those with specific mechanical, optical, or castable properties.

While FDM printing offers affordability, material versatility, and larger print volumes, it may result in visible layer lines and limited surface smoothness. Post-processing, such as sanding and painting, is often required to achieve the desired finish. Resin printing, on the other hand, provides exceptional surface quality and intricate details but can be more expensive, require special handling of liquid resin and have a smaller build volume compared to FDM printers.

I should warn you that resin 3D printing requires a lot more caution and consideration than FDM 3D printing. Resin is a rather nasty chemical that should never make contact with exposed skin. It also comes with a nasty odor that shouldnt be used in a confined, non-ventilated space. The parts must be handled and post-processed prior to the curing process so a work area that can be contained and cleaned is necessary.

Unleash Your Creativity with Fusion 360: The Ultimate 3D Modeling Software

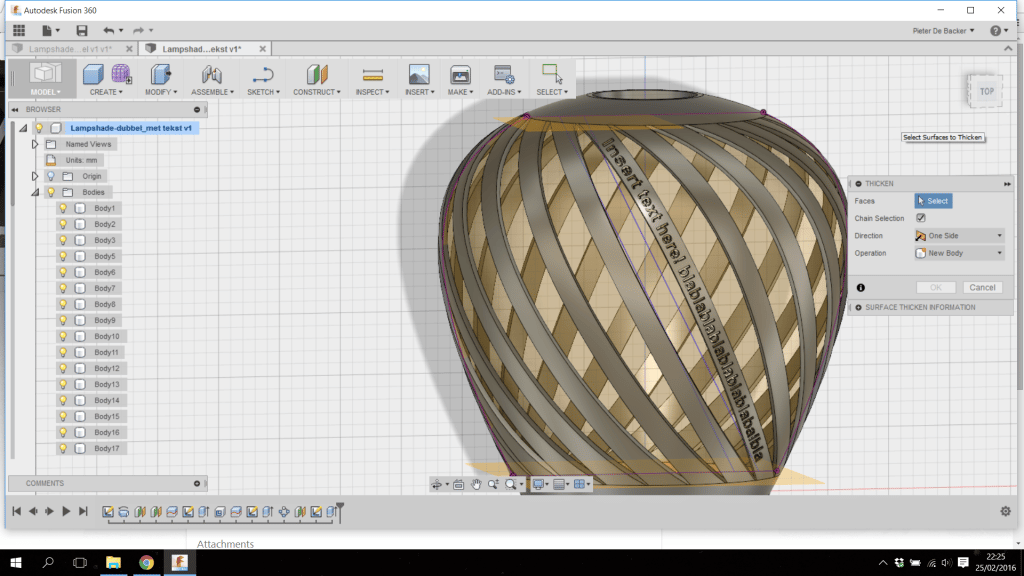

This article highlights the numerous benefits of using Fusion 360 for 3D modeling, from its versatile feature set to its seamless integration with other tools and platforms. Whether a beginner or an experienced 3D modeler, Fusion 360 is the ultimate tool for bringing your ideas to life.

3D modeling is a powerful tool for designers, engineers, and makers. Whether you are creating a prototype for a product, a detailed design for a complex machine, or a concept for a new design, 3D modeling software is an essential tool for bringing your ideas to life. One of the best 3D modeling software programs available today is Fusion 360, and in this article, we will explore its benefits and how to use it for free.

One of the biggest benefits of Fusion 360 is its versatility. Whether a beginner or an experienced 3D modeler, Fusion 360 has the tools and features to create detailed, accurate, and professional-looking models. With its intuitive interface and comprehensive feature set, Fusion 360 makes it easy to create anything from simple sketches to complex assemblies.

Another benefit of Fusion 360 is its integration with other tools and platforms. Fusion 360 integrates with Autodesks extensive design and engineering tools portfolio, making it easier to work with other team members, exchange data, and collaborate on projects. Fusion 360 integrates with various other platforms, such as 3D printing services, CAM software, and simulation tools, making it a one-stop shop for all your design needs.

So, how can you use Fusion 360 for free? Autodesk offers a free version of Fusion 360 for students, hobbyists, and startups, giving you access to the full feature set for non-commercial use. If you are a student or hobbyist, you can quickly sign up for the free version and start using Fusion 360 today. If you are a startup, you can apply for the Autodesk Startup Program, which provides free access to Fusion 360 and other Autodesk tools.

In conclusion, Fusion 360 is a powerful and versatile 3D modeling software that offers a range of benefits for designers, engineers, and makers. Whether a beginner or an experienced 3D modeler, Fusion 360 has the tools and features to bring your ideas to life. Its integration with other tools and platforms, Fusion 360, makes it easy to work with other team members, exchange data, and collaborate on projects. And with its free version for students, hobbyists, and startups, there has never been a better time to start using Fusion 360.

FAQ

Why is Fusion 360 so popular?Since then, interest in Fusion 360 has only increased. Its widespread use results from its affordable price, flexible options, and diverse applications. The software can be used for motion animation, electrical circuit design, generative design, failure mode simulation, and 3D modeling.

Solid models can be easily created with Fusion 360s comprehensive set of 3D modeling tools. Additionally, this Autodesk software is very adaptable and somewhat simpler to use. With its excellent push/pull tool, you can create fantastic organic shapes and surfaces.

Why is Fusion 360 better than AutoCAD?While still offering tools for animations, 3D modeling, simulation, blueprinting, woodworking with CNC, and 3D printing, Fusion 360 is more affordable than AutoCAD. Hobbyists, independent design studios, mechanical design students, and 3D printing enthusiasts frequently use it.

Is Fusion 360 good for 3D modeling?Discover the definition of 3D modeling software and why Autodesk Fusion 360 is the best 3D modeling program for both novices and professionals. There is typically a learning curve, like when learning any new skill. Particularly when it comes to 3D modeling, this is true.

Are you a student, hobbyist, or startup needing a powerful 3D modeling tool?

Let us know in the comments below or on ourFacebook pageto let us know your ideas, and we would appreciate seeing pictures of your works of art!

Beginners Guide to 3D Printing Warhammer Models

Warhammer fan looking to explore the world of 3D printing? Get started with this beginners guide to 3D printing Warhammer models!

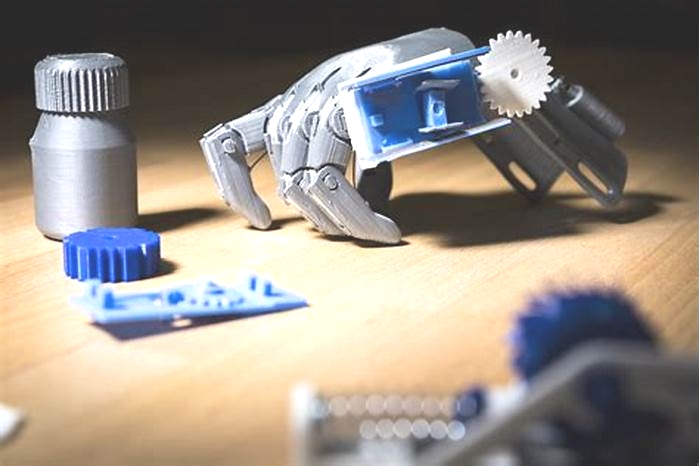

With the advent of 3D printing technology, creating intricate and detailed models has become easier than ever before.

Whether youre a beginner or an experienced Warhammer enthusiast, 3D printing allows you to bring your imagination to life like never before.

From creating custom miniatures to designing unique terrain pieces, the possibilities are endless. With the right equipment, software and a few tips and tricks, you can start creating your very own Warhammer models in no time. So, get ready to unleash your creativity and take your Warhammer hobby to the next level with 3D printing!

Of course, its important to start by stating that Games Workshop is not too kind on people printing their models.

How to Start 3d Printing Warhammer Miniatures

To start 3D printing, you will need a few key things:

- A 3D printer: There are many different types of 3D printers available on the market, with varying levels of complexity and cost. Research and compare different options to find one that fits your needs and budget.

- 3D modeling software: To create a 3D model, you will need to use a software program that allows you to design and manipulate 3D objects. Some popular options include Tinkercad, SketchUp, and Blender.

- 3D printer filament: This is the material that is used to create the physical object. Common types of filament include ABS and PLA, which come in a variety of colors.

- A computer: To control your 3D printer and to run the 3D modeling software, you will need a computer.

Once you have these things, you can begin creating your own models, and print them on your 3D printer. Its helpful to start with simple models and gradually progress to more complex projects.

Where do you find models to print

There are several places where you can find things to 3D print:

- Online marketplaces: Websites like Thingiverse, MyMiniFactory, and Youmagine offer a wide variety of 3D models that you can download and print for free. You can also find paid models on these marketplaces.

- Social media: Many designers and makers share their 3D models on social media platforms like Instagram and Facebook. You can also join 3D printing groups on these platforms to find models and connect with other 3D printing enthusiasts.

- Open-source libraries: Websites like GitHub and OpenSCAD provide a platform for designers to share their 3D models and designs under open-source licenses.

- 3D scanning: You can use 3D scanning devices to scan physical objects and then use the digital files to print a replica of the object. This is more complex than it sounds, and probably not the best place to begin.

- Creating your own: You can use 3D modeling software like Tinkercad, SketchUp, and Blender to create your own 3D models. You can check out this pretty thorough guide from Spikey Bits on creating your own miniatures.

- Custom 3D Printing Service: Some companies offer a custom 3D printing service, where you can upload your own design and they will print it for you. Friends with 3D Printers are also handy, and can often be paid in drinks.

Introduction to 3D Printing

Before we dive into the best 3D printers on the market, lets take a quick look at what 3D printing is and how it works. 3D printing is a process of creating three-dimensional objects from a digital file using a 3D printer.

The printer reads the file and prints the object layer by layer until it is complete. 3D printing is used in various industries, including healthcare, aerospace, architecture, and fashion, to name a few.

One of the biggest advantages of 3D printing is its ability to create complex geometries and custom designs that would be impossible to achieve using traditional manufacturing methods. It is also better than sculpting when it comes to replicating the same piece multiple times; custom shoulder plates for example.

Factors to Consider When Choosing a 3D Printer

Choosing the right 3D printer can be a daunting task, especially if youre new to the world of 3D printing.

Here are some factors you should consider when choosing a 3D printer:

Type of Printer

There are several types of 3D printers available in the market, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and DLP (Digital Light Processing). Each type of printer has its own strengths and weaknesses, and the type of printer you choose will depend on the kind of objects you want to print and the level of detail you require.

Terrain is usually more forgiving, where intricate bits, like faces will require a more precise material (and often, a costlier printer)

Build Volume

The build volume refers to the maximum size of the object that can be printed. If youre planning to print large objects, youll need a printer with a larger build volume.

However, keep in mind that larger build volumes also mean larger printers, which can take up a lot of space.

Resolution

Resolution refers to the level of detail that a printer can achieve. The higher the resolution, the more detailed the object will be. However, higher resolution also means slower printing speeds, so youll need to find a balance between resolution and printing speed.

Filament Compatibility

If youre using an FDM printer, youll need to consider the type of filament that the printer is compatible with. PLA and ABS are the most commonly used filaments.

This, sadly, is more of a trial and error method. Once you find the filament and settings that work for you, stick with it.

Maintenance and troubleshooting tips for 3D printers

Maintaining a 3D printer is important to ensure that it continues to function optimally. Here are some tips on how to maintain your 3D printer:

- Clean the printer regularly to remove dust and debris.

- Check the belts and screws to ensure that they are tight.

- Lubricate the moving parts of the printer to ensure smooth movement.

- Use high-quality filaments to ensure that the printer produces high-quality prints.

- Keep the printer in a clean and dry environment to avoid moisture damage.

In case you encounter any issues with your 3D printer, here are some troubleshooting tips:

- Check the filament and ensure that it is loaded correctly.

- Check the print bed and ensure that it is level.

- Check the nozzle and ensure that it is clean.

- Check the temperature settings and ensure that they are correct.

- Check the slicer settings and ensure that they are optimized for the material being used.

You can also check out these 3D printing tools, guaranteed to make your printing experience better.