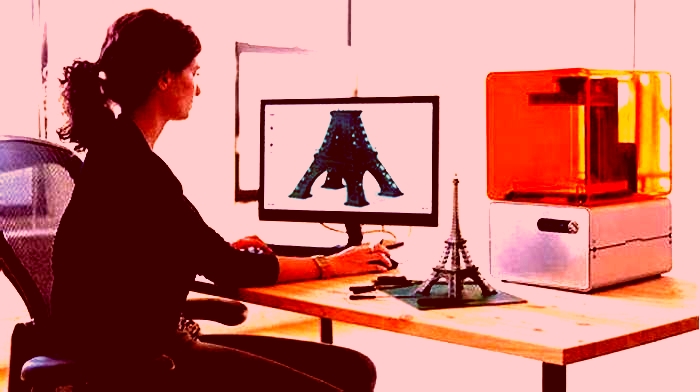

3D Printing for Prototyping and Product Design Utilizing 3D Printers in a Professional Setting

Rapid Prototyping in 3D Printing: Definition, Types, and Methods

The pros and cons of rapid prototyping relate mostly to the speed and cost of creating a part. One main advantage is that an individual can gain a feel for how the final design will look and operate. This allows improvements and changes to be implemented quite early before final production takes place. The drawback with rapid prototyping is that, sometimes, product developers tend to lavish a lot of attention on a limited prototype. This prevents them from doing a complete analysis of the product to check for its strengths and weaknesses so that the quality of the product may not be compromised. Another benefit of the process is its cost-efficiency. It is an automated process that requires few people to operate.

What is Rapid Prototyping Used for?

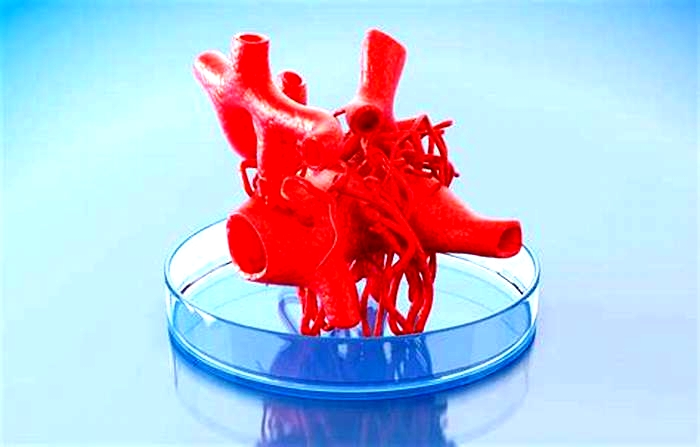

Rapid prototyping is used in making physical and digital models. It is a very fast and efficient process that helps in the production of prototypes. Rapid prototyping aids in the assessment of a part for faults or issues that need to be resolved before the final iteration takes place.

What is the Rapid Prototyping Method?

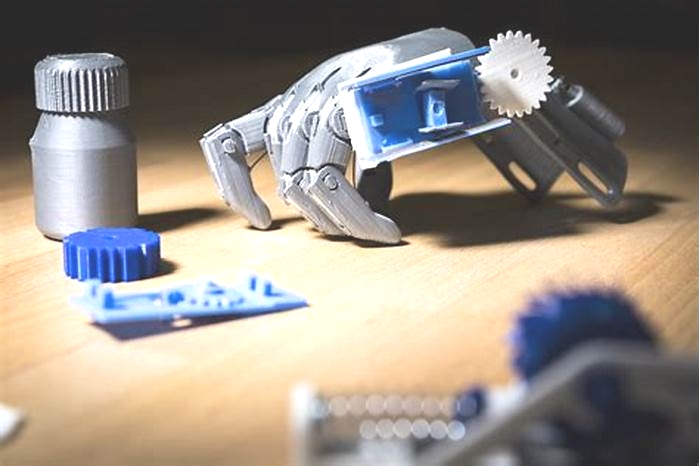

The rapid prototyping method includes the fast production of a physical part using a variety of techniques, including 3D printing (an additive manufacturing process), high-speed machining (a subtractive manufacturing process), injection molding, and casting.

How Does Rapid Prototyping Work?

Rapid prototyping works by:

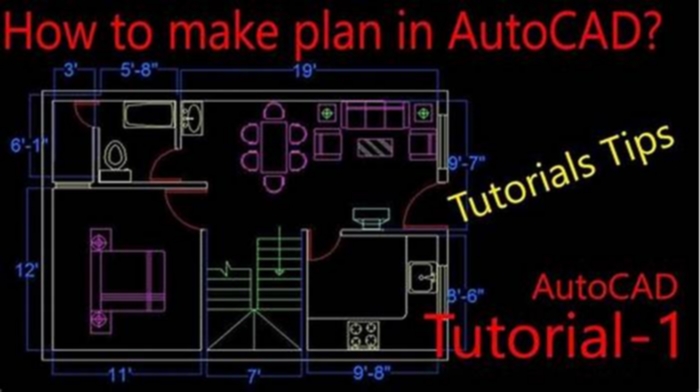

- Computer-Aided Design (CAD) software generates a digital 3D model of the part. The CAD model is converted into a file format (examples are: STL, OBJ, and DXF).

- Slicing software slices down the 3D model into a series of 2D layered slices.

- The 3D printer interprets these slices in the actual build process until the object is complete.

Supportive structures may be needed in the prototyping model to avoid distortion or warping. Prototypes may require post-processing such as sanding, cleaning, and painting, to achieve a good surface finish.

How to Use Rapid Prototyping?

Rapid prototyping is used to reduce cost and lead time when producing a new product. Prototypes first exist as a concept before a physical validation of the model (called proof of concept) is produced. This enables a team to know where to go in the next step of the iteration process. To maximize a rapid prototyping process, some things have to be considered, including:

- The early stage prototypes are almost always the roughest. They are usually made with different materials and in different colors.

- After the prototype has been identified in its roughest form, the next step is post-processing, which helps improve the quality of the product and meet requirements

- After every process, the prototype is transitioned to a functional prototype: although it may not be fully functional yet. At this stage, prototypes are usually created with materials that will be used in the development of the end product. The performance is assessed to see if it closely matches the desired result. Questions that may arise include: how well does it adapt to a stipulated condition, does it fit at the proposed point in an assembly?

Why Do Engineers Use Rapid Prototyping?

Engineers use rapid prototyping in quickly developing prototype models directly from CAD files. Rather than simply relying on the conceptual framework, engineers can revise their designs based on the feedback from real-world testing. They can see how the final or actual product looks and operates before moving on to mass production.